Looking to improve quality & reduce costs of manufacturing?

UNDERSTANDING VARIATION IS THE ANSWER!

“A phenomenon will be said to be controlled [predictable] when, through the use of past experience, we can predict, at least within limits, how the phenomenon will behave in the future.”

— Walter A. Shewhart, Economic Control of Quality of Manufactured Product

“The process principle states that sequential outputs of a process are subject to some degree of difference, whether we can measure those differences or not.”

— Jim Lehner, The Virus of Variation

The challenge of manufacturing

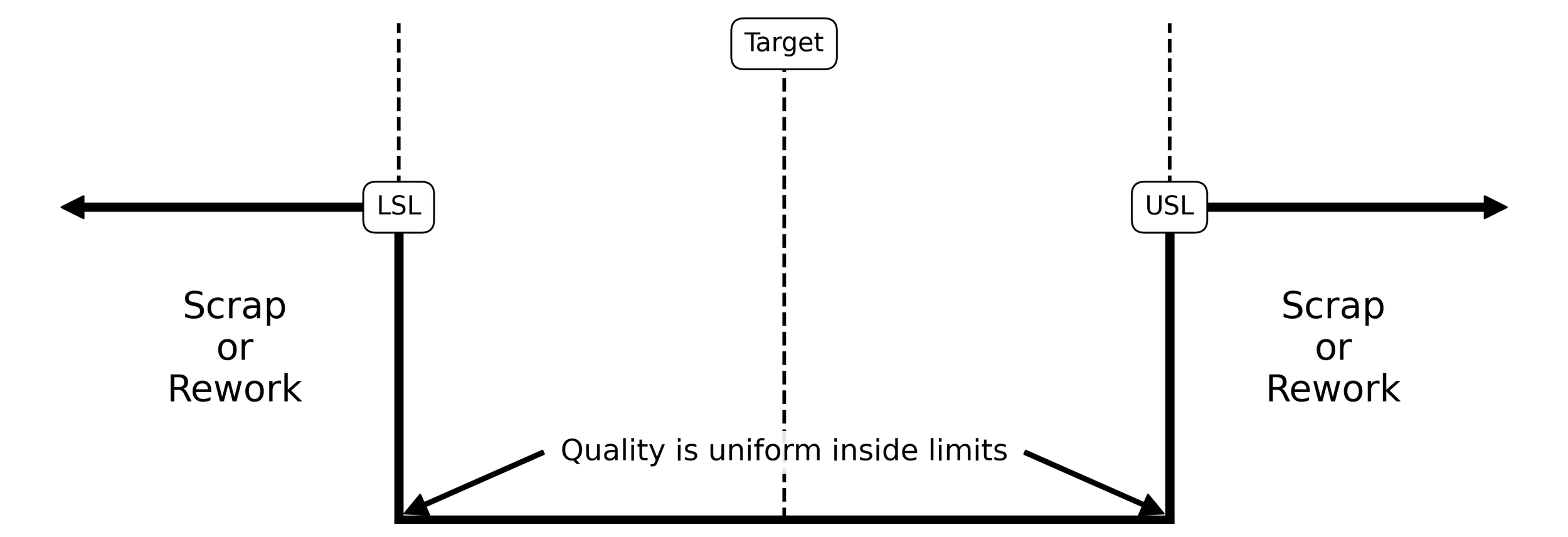

For as long as we’ve been making things, we’ve made efforts to make things the same. And yet, even with all our efforts, differences persist. Why is that and how can these seemingly unavoidable differences be overcome? This is the challenge of manufacturing.

How to build an XmR chart

Understanding variation is only possible when you know how to build process behavior charts. In this six-step guide, you’ll learn how to build the swiss-army knife of process behavior charts: the XmR chart.

Characterization

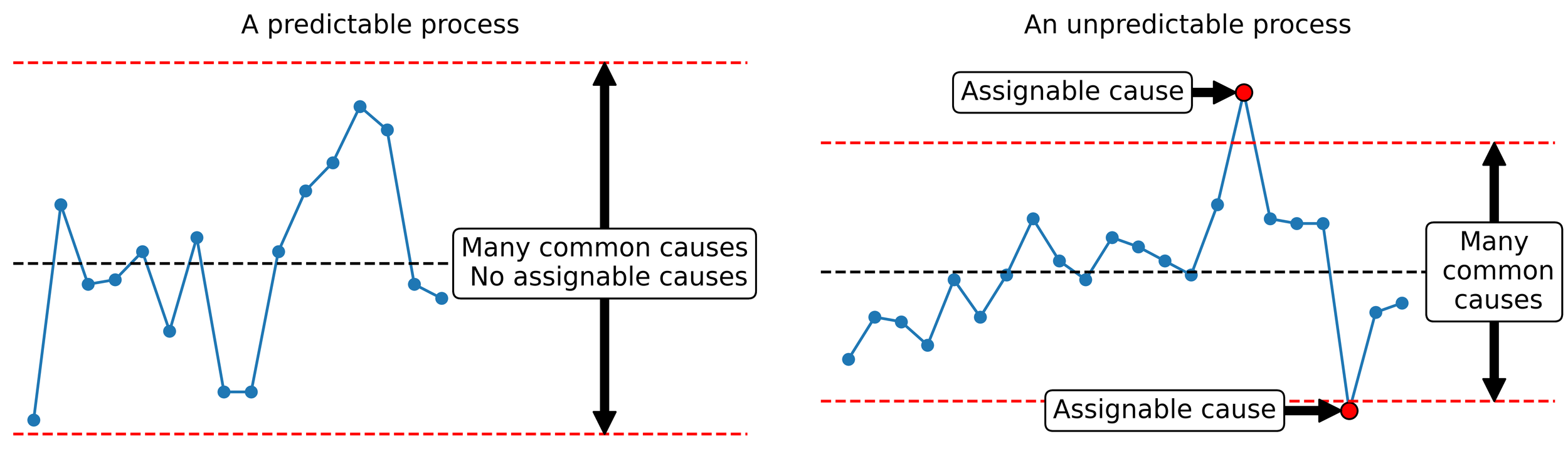

Characterization is the task of determining if future process behavior can be predicted within limits. If it can, a process is characterized as predictable. If it cannot a process is characterized as unpredictable. Do you know what conditions satisfy each characterization?

“The job of a manager is to work on the system, to improve it, with the help of the workers.”

— Myron Tribus, The Germ Theory of Management