What is variation & why you should care

It is an inconvenient fact of manufacturing that no matter how hard we try, the sequential outputs of processes are subject to some degree of difference. That is, no two things produced by the same process will ever be the same. Whether we like it or not, variation always asserts an influence.

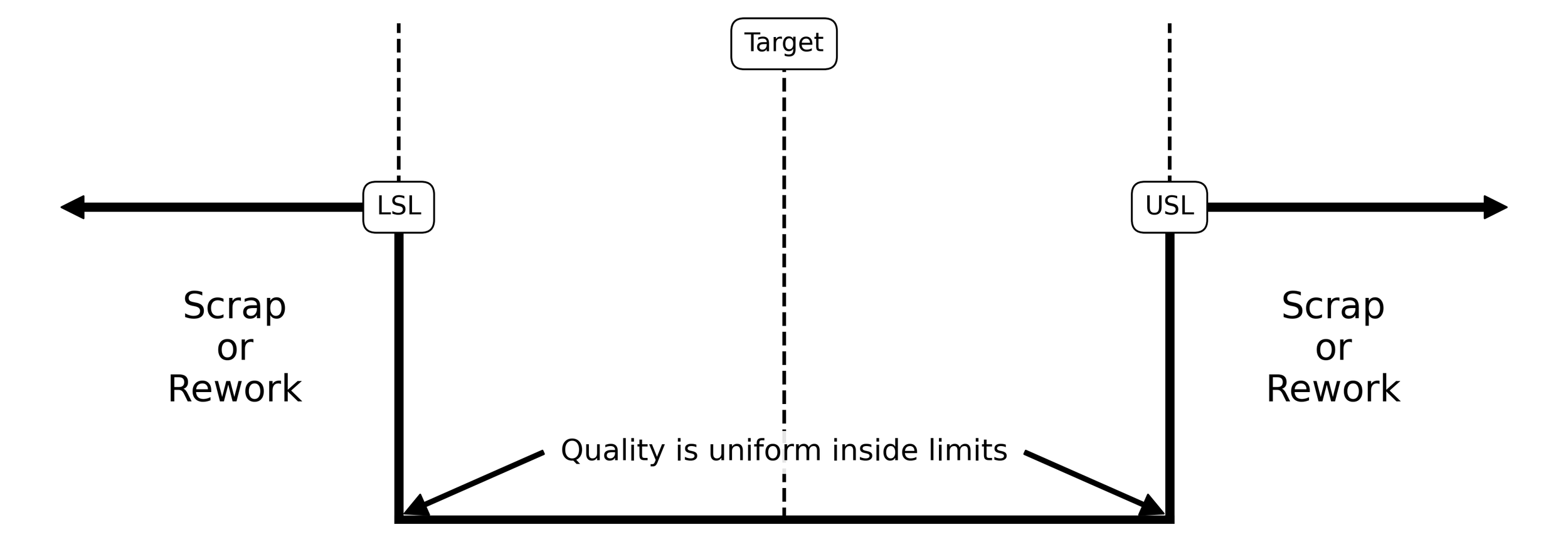

As important as this fundamental principle may be, education and industry reliably overlook it. Instead of accepting variation as the framework within which all manufacturing takes place, an overly simplified model is used. This model applies 18th century logic to 21st century efforts. It deems anything that falls inside the specification (spec) limits as “good” and anything that falls outside the spec limits as “bad.” This reduces manufacturing to a binary model of “good enough” that is epitomized by the rectangular loss function shown in Figure 1.

Figure 1. A square loss function deems everything inside of the specification limits “good” and everything outside of the specification limits “bad.”

While the binary model of “good enough” is thought to be, well, good enough, it is a relic of the past that has no place in modern manufacturing. The volume and scale of today’s production processes and the data that they produce make “good enough” a liability. It spawns opportunities for processes to produce scarp and encourages the practice of “fire fighting” that consumes time and resources, often with nothing to show for it.

Services: How we can help!

The practice of good enough does not need to continue. A future in which manufacturing processes produce products of world-class quality is within reach and why The Broken Quality Initiative was created.

We teach the theory and practice that is foundational to understanding variation. In doing so, we help organizations reduce costs and improve quality in ways that those that still subscribe to the “good enough” model can only dream.

Is the cost of poor quality too high? We can help!

Want to make sense of production data? We can help!

Need to improve supplier quality? We can help!

Tired of scrap and rework? We can help!

Missing delivery targets? We can help!

Tired of fire-fighting? We can help!

The framework used by The Broken Quality Initiative is industry and product agnostic. This means what your manufacturing doesn’t matter. Whether its jet engines, batteries, catheters, electrical connectors, insulin pumps, electric aircraft, automated manufacturing lines, or anything in between, our method for understanding variation will help you reduce costs and improve quality. We’ll help you manufacture more robust and reliable products by understanding the unavoidable influence of variation.

Email QualityIsBroken@gmail.com for details.

-

Process improvement is not a spectator sport. It is a method and technique with value that is best achieved by doing.

Working directly with you and your team, we will review the current state of your manufacturing processes and establish a path forward that reduces costs and improves quality.

Email QualityIsBroken@gmail.com for details.

-

Our one day Understanding Variation course teaches the theory and practice that makes reducing costs and improving quality possible.

Email QualityIsBroken@gmail.com for details.

-

The “good enough” approach to manufacturing endures because that is what is taught in schools.

To put an end to this, we are looking for higher education partners that will help us advance the theory and practice that governs modern manufacturing.

Email QualityIsBroken@gmail.com for details.

-

Professional speaking engagements and guest lectures on topics including process improvement, Statistical Process Control (SPC), the definition of quality, and data-driven improvement.

Email QualityIsBroken@gmail.com for details.