What is The Broken Quality Initiative?

Quality has become an overused term of little substance. It has become a pervasive replacement for the dimensional and performance characteristics of parts and products that we have been trained to assume are synonymous with better. But better with respect to what? Better than the competition? Better than before? Better than expectations? Quality under the guise of better is subjective and inert. This leaves it vulnerable to wants and whims rather than analysis. It leaves it devoid of a definition that is part, product, process, and industry agnostic.

The Broken Quality Initiative is a response to our collective failures to establish manufacturing as a science and quality as a discipline. It is a response to the pervasive lack of knowledge of variation and the only tool capable of making sense of it: the process behavior chart (control chart).

This lack of knowledge is reflected in the often haphazard and chaotic methods that individuals, teams, and organizations use to improve quality and reduce costs. Rather than work to understand and eliminate the sources of variation that make processes erratic and unpredictable, inordinate amounts of time and attention are dedicated to gut feelings and guesswork. While this sentiment is often accompanied by good intentions and hard work, the lack of theory to guide actions reliably digs the hole deeper. It reliably distracts and undermines organizations from producing products of world-class quality.

Since the seminal work of the physicist Walter Shewhart at Bell Telephone Laboratories in the mid-1920s , a method and tool capable of making sense of variation has been at our fingertips. This method, Statistical Process Control (SPC), and this tool, the process behavior chart (control chart), have kept industry busy improving quality and reducing costs for more than a century. It is due time that we put Shewhart’s method and tool to work so engineers and industry alike can turn data into insights and insights into actions that reduce costs and improve quality.

Table of Contents

What is the Broken Quality Initiative?

“No one gives a hoot about profits—if they did they would be interested in learning better ways to make them.”

— Deming’s First Theorem

How is quality broken?

Conformance to specification has come to define quality as a field and practice. Rather than aim to operate processes on-target with minimum variance—the definition of quality established by Dr. Genichi Taguchi in September 1960—quality, as reflected in ISO 9000:2015 Clause 3.5.1, is defined as the degree to which a set of inherent characteristics of an object fulfills requirements.

While on its face this definition of quality seems sensible, after all no customer in their right mind will accept product that does not fulfill requirements, it reinforces the perspective that quality is binary. It bolsters the widely held but wrong belief that the measured characteristics of parts, products, services, processes, and systems are either good or bad, conforming or non-conforming.

As a product of this binary view, the quality landscape has been infected with tools, techniques, methods, and fads that are too busy mopping to turn off the water. It has been reduced to efforts that attempt to improve quality and reduce costs with no recognition or knowledge of variation and its unrepentant influence. This results in actions that ignore the reality that variation is always at work. It ensures that defects will be produced in the future and world-class quality will never be achieved.

Quality as a field and practice is broken because it lacks an understanding of variation and the only tool capable of making sense of variation, the process behavior chart. While we will not be able to eradicate the virus of variation overnight, it is the aim of The Broken Quality Initiative to continue the immunization campaign started by Walter Shewhart in the mid-1920s at Bell Labs. It is our goal to provide engineers and industry with the knowledge and knowhow to understand variation and eliminate its influence using process behavior charts (control charts).

How do we fix quality?

Fixing quality specifically, and manufacturing generally, is a single job with two parts: theory and practice.

Theory requires knowledge of variation—specifically, an understanding of the two types of variation: common causes of routine variation and assignable causes of exceptional variation. Without the knowledge of variation, improvement efforts rely on luck rather than analysis. The consequences of this have backed manufacturing and quality into a dead end. Individuals and teams operate in an environment where sometimes things get better and sometimes things get worse, with no understanding of either outcome.

Practice puts the theory of variation to work by doing. It is expressed by spending time with the data-generating process (DGP) and performing detective work. It manifests through the construction of process behavior charts and responding to the insights they reveal. Without practice, the knowledge of variation is useless.

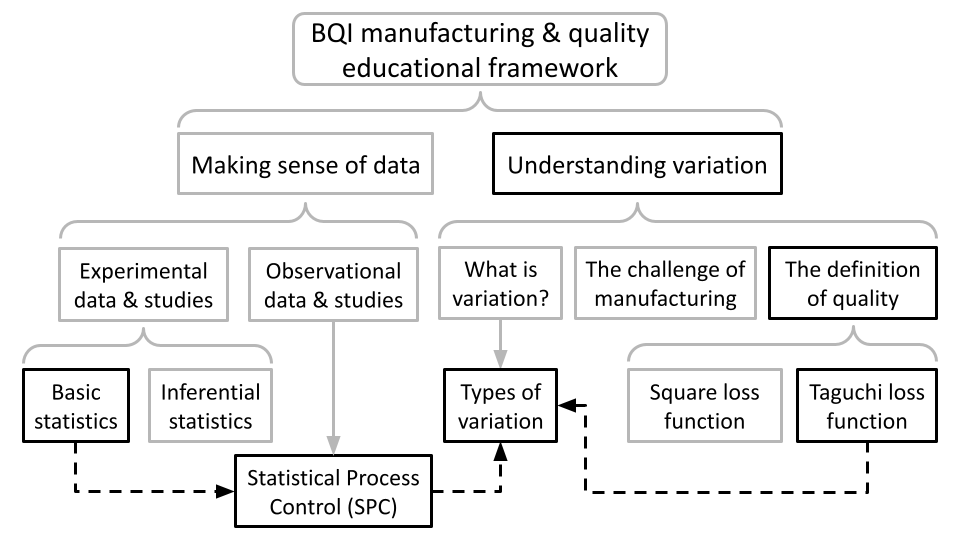

To this end, The Broken Quality Initiative has developed a framework to address the failures of quality and manufacturing as they are practiced today (see Figure 1).

Figure 1. A topical overview of items included in the BQI educational framework with core topics highlighted.

The first leg of this framework teaches students how to make sense of data. This begins by dividing the data landscape into two broad classifications—experimental data and observational data. This distinction leads to discussion about the two types of studies (experimental studies and observational studies) and the way of thinking associated with each. With these distinctions in hand, subsequent discussion explores how the tools of statistics and Statistical Process Control (SPC) are distinct, even though they borrow from each other. It explores how, in the words of American statistician and quality control expert Donald J. Wheeler, “two things sharing a common name can still be different” (Statistics and SPC, 2014).

The second leg of this framework teaches an understanding of variation. It explores seminal questions such as: What is the purpose of manufacturing? What is variation? How do we define quality? These theory focused discussions form a broad framework that can be applied to real world problems. They provide students with a way to think about manufacturing as an effort to produce products that are virtually uniform instead of efforts to meet specifications.

The theory and ideas discussed in the two legs of this educational framework are underpinned by practice. This practice is facilitated by spreadsheet software like Google Sheets and Microsoft Excel, and programming languages like Python. It challenges students to spend time with the DGP and perform detective work. These tools and efforts put students in the proverbial driver seat. They ensure that the new way of thinking cultivated by exposure to theory is reinforced by doing. Without this rubber meets the road approach, the growth and development that comes from doing, failing, refining, and doing again remains out of reach.

The Broken Quality Initiative is always looking for opportunities to partner with educational organizations and speak with students. If you would like to discuss our framework further email us at QualityIsBroken@gmail.com.

Who is the BQI?

The Broken Quality Initiative was founded by Jim Lehner in 2024 as a response to the pervasive lack of knowledge of variation in business and industry. A graduate of Worcester Polytechnic Institute (WPI), with an undergraduate degree in Mechanical Engineering and a graduate degree in Manufacturing Engineering, Jim’s professional experience has exposed him to variety of problems in a variety of industries (automotive, aerospace, industrial machining, medical device, healthcare).

Regardless of the problem and regardless of the industry, one underlying truth quickly made itself clear in Jim’s professional journey. If we are to manufacture products of world-class quality we must, first and foremost, understand variation. Without an understanding of variation you are flying blind. You are leaving your success to luck and chance rather than analysis and insight.

But luck and chance cannot reliably and repeatedly produce results. They do not and will not ever combine to form a comprehensive method. To do that requires tools and techniques that allow us to turn data into insights and insights into actions that result in change.

Luckily, for more than a century, a method and tool capable of such a task has helped industry understand and address the virus of variation. That method, Statistical Process Control (SPC), and that tool, the process behavior chart (control chart), is how we reliably and repeatedly improve quality and reduce costs. It is how we transform data into insights and insights into actions that result in quantifiable and lasting change.