Centered Performance Ratio, Pp

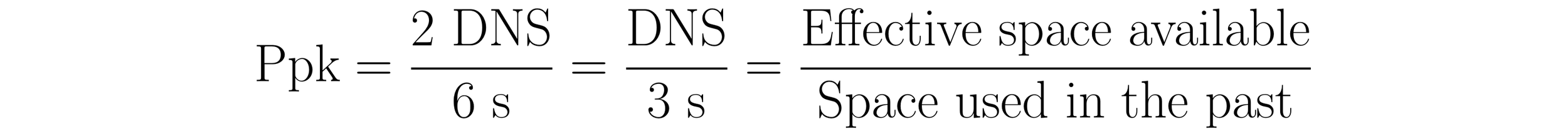

The Centered Performance Ratio, Ppk, compares the effective space available to the space used in the past by the process, as defined by 6 s. The effective space available, as opposed to the space available, describes the location of a process using the distance to the nearer specification, 2 DNS. Thus, the formula for the Centered Performance Ratio is written as:

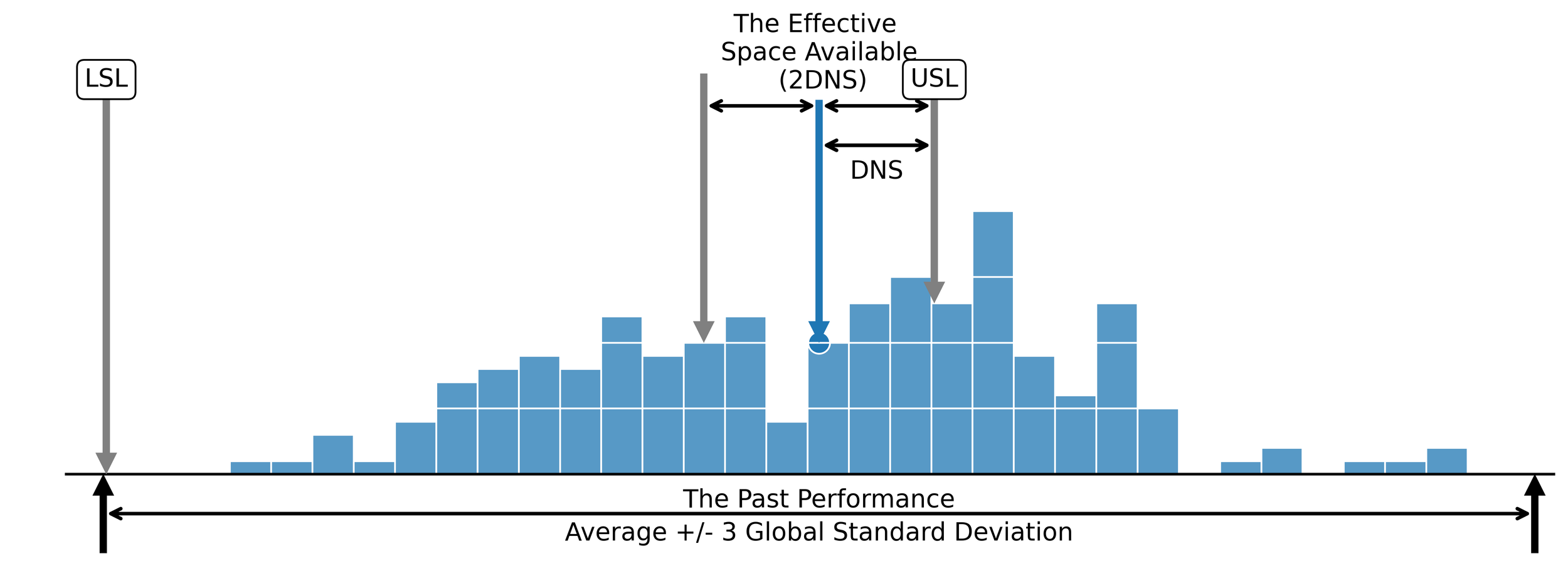

The relationship between the effective space available and the space used in the past is clarified in Figure 1. Here, a generic distribution of individual values is shown in the context of the effective space available (2 DNS), the space available (tolerance),and the space used in the past, as defined by the term Average ± 3 s. The s in the term 6 s is the global standard deviation statistic. It should not be confused with the within-subgroup measure of dispersion Sigma(X), the defining term in the denominator of the Capability Ratio and the Centered Capability Ratio.

Figure 1. The relationship between the effective space available and the space used in the past by the process.

A word of warning

The Centered Performance Ratio, like all process parameters, is not well-defined until the underlying causal system is operated predictably. Whenever a process is operated unpredictably, that is it is influenced by both common causes of routine variation and assignable causes of exceptional variation, the process parameters, including the process mean, the process standard deviation, and the process capability indices, will change over time. While we can always compute statistics regardless of the characterization (predictable or unpredictable), the only time this arithmetic can be used to estimate process parameters is when the process is operated predictably. When a process is operated unpredictably “the process parameters are changing and are therefore divorced from the statistics” used to calculate them. (Wheeler, More Capability Confusion, (Quality Digest, May 2017), 2).

It is for the above reasons that the Process Capability Indices should always be reported with the additional context of a process behavior chart and a capability histogram. The process behavior chart will characterize process behavior as either predictable or unpredictable. In doing so, it reveals the voice of the process. The capability histogram will visualize the relationship between the specification limits (space available) and the distribution. In doing so, the capability histogram reveals the relationship between the process and the voice of the customer.