How do we fix quality?

Fixing quality specifically, and manufacturing generally, is a single job with two parts: theory and practice.

Theory requires knowledge of variation—specifically, an understanding of the two types of variation: common causes of routine variation and assignable causes of exceptional variation. Without the knowledge of variation, improvement efforts rely on luck rather than analysis. The consequences of this have backed manufacturing and quality into a dead end. Individuals and teams operate in an environment where sometimes things get better and sometimes things get worse, with no understanding of either outcome.

Practice puts the theory of variation to work by doing. It is expressed by spending time with the data-generating process (DGP) and performing detective work. It manifests through the construction of process behavior charts and responding to the insights they reveal. Without practice, the knowledge of variation is useless.

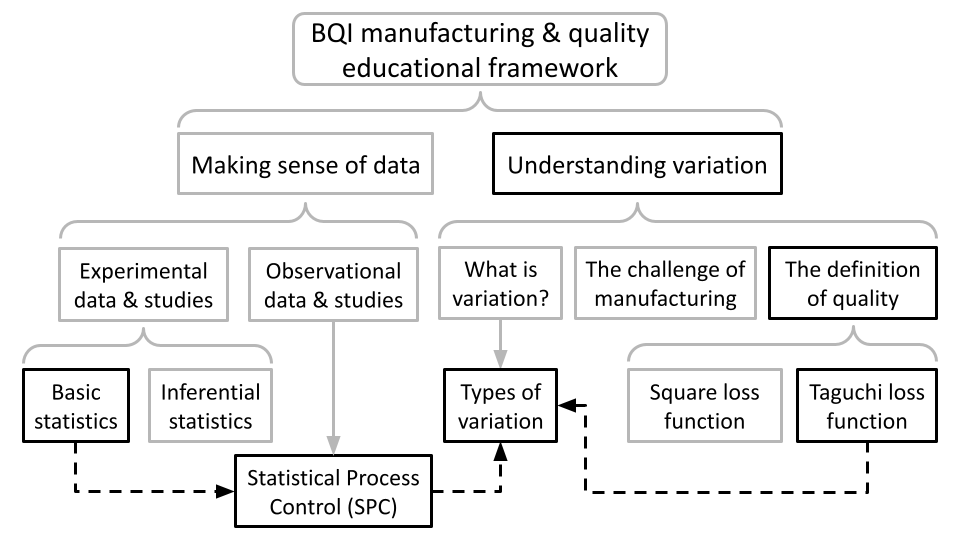

To this end, The Broken Quality Initiative has developed a framework to address the failures of quality and manufacturing as they are practiced today (see Figure 1).

Figure 1. An overview of the topics included in the BQI educational framework with core topics emphasized.

The first leg of this framework teaches students how to make sense of data. This begins by dividing the data landscape into two broad classifications—experimental data and observational data. This distinction leads to discussion about the two types of studies (experimental studies and observational studies) and the way of thinking associated with each. With these distinctions in hand, subsequent discussion explores how the tools of statistics and Statistical Process Control (SPC) are distinct, even though they borrow from each other. It explores how, in the words of American statistician and quality control expert Donald J. Wheeler, “two things sharing a common name can still be different” (Statistics and SPC, 2014).

The second leg of this framework teaches an understanding of variation. It explores seminal questions such as: What is the purpose of manufacturing? What is variation? How do we define quality? These theory focused discussions form a broad framework that can be applied to real world problems. They provide students with a way to think about manufacturing as an effort to produce products that are virtually uniform instead of efforts to meet specifications.

The theory and ideas discussed in the two legs of this educational framework are underpinned by practice. This practice is facilitated by spreadsheet software like Google Sheets and Microsoft Excel, and programming languages like Python. It challenges students to spend time with the DGP and perform detective work. These tools and efforts put students in the proverbial driver seat. They ensure that the new way of thinking cultivated by exposure to theory is reinforced by doing. Without this rubber meets the road approach, the growth and development that comes from doing, failing, refining, and doing again remains out of reach.

The Broken Quality Initiative is always looking for opportunities to partner with educational organizations and speak with students. If you would like to discuss our framework further email us at QualityIsBroken@gmail.com.